Steel Business

Our steel business focuses on precision manufacturing of high-quality steel components for the automotive industry. We utilize advanced production lines including forging, machining, heat treatment, plating, and assembly processes to deliver superior products that meet Yamaha's stringent quality standards worldwide.

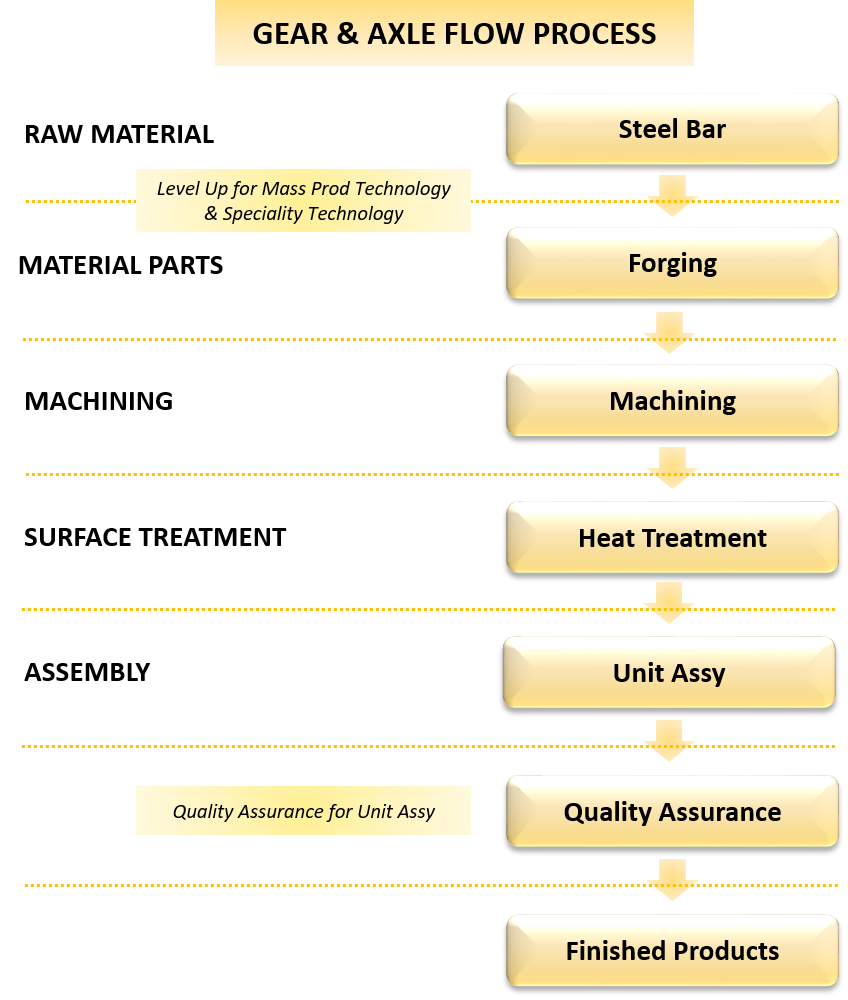

Gear & Axle

Divided into five production lines: Forging, Machining, Heat Treatment, Plating, and Assy.

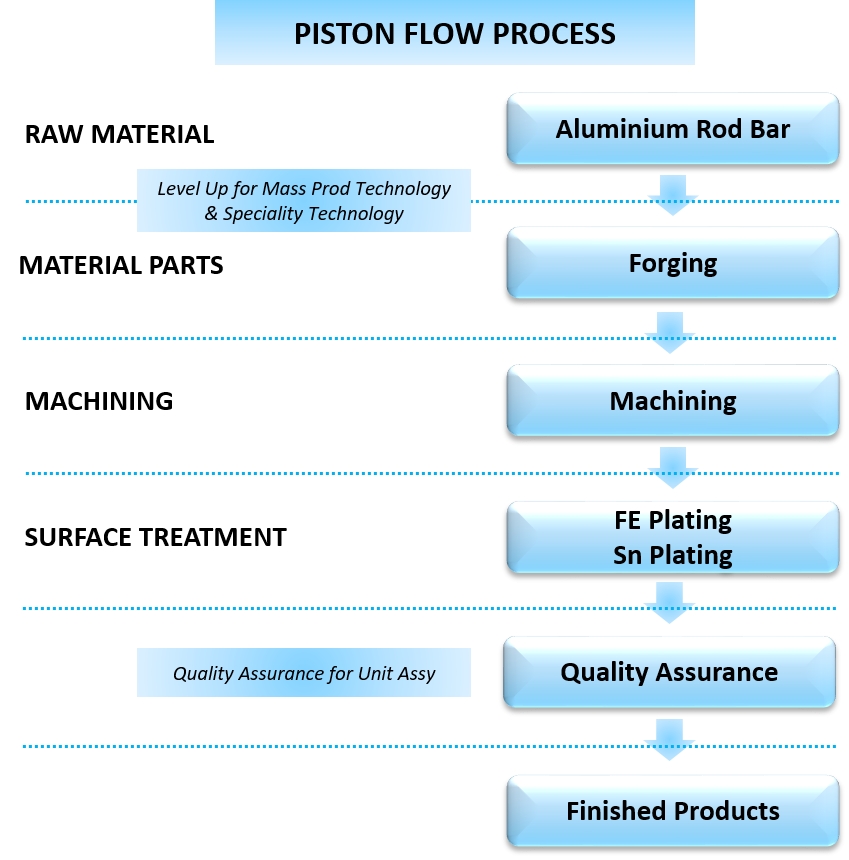

Piston

Consist of three production lines: Forging, Machining, and Plating.

Whole manufacturing process is conducted in YPMI factory from raw material into finished good.

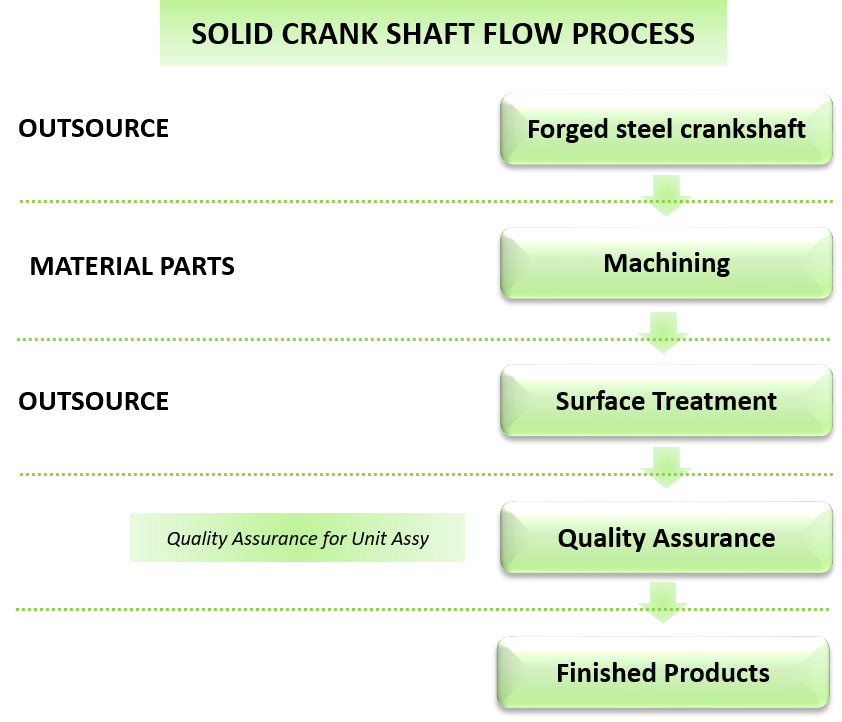

Solid Crank Shaft

Divide into three production lines: Machining Before H/T, Machining After H/T &Assy.

Forging and H/T manufacturing process is conducted outside YPMI Flow:

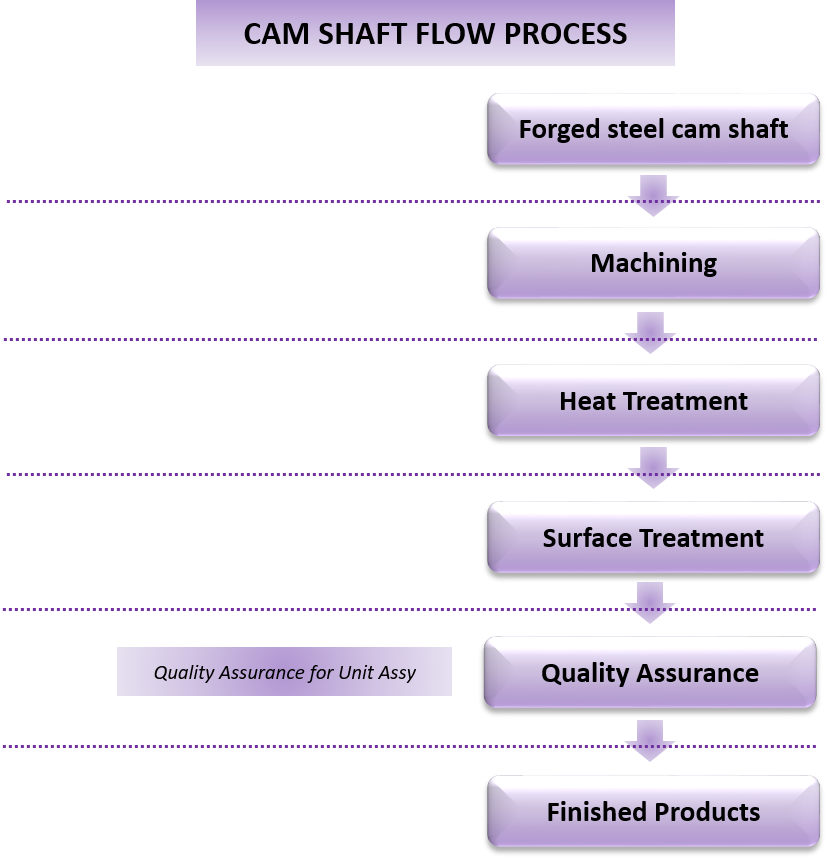

Cam Shaft

Divided into three production lines: Machining Before, Heat Treatment, Machining After.

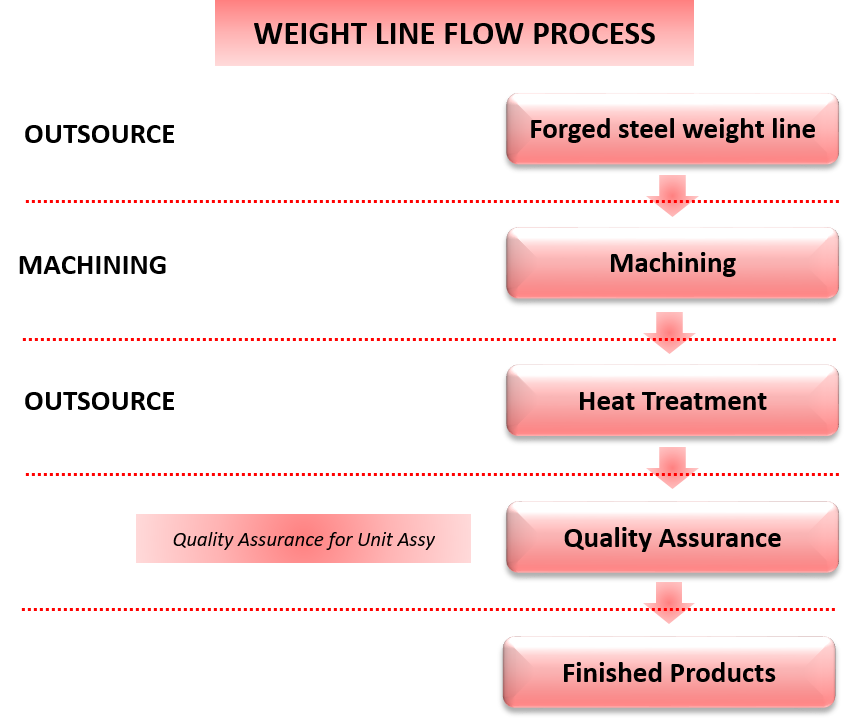

Weight Line

Divided into three production lines: Machining Before H/T, Heat Treatment, Machining After H/T. The flow is

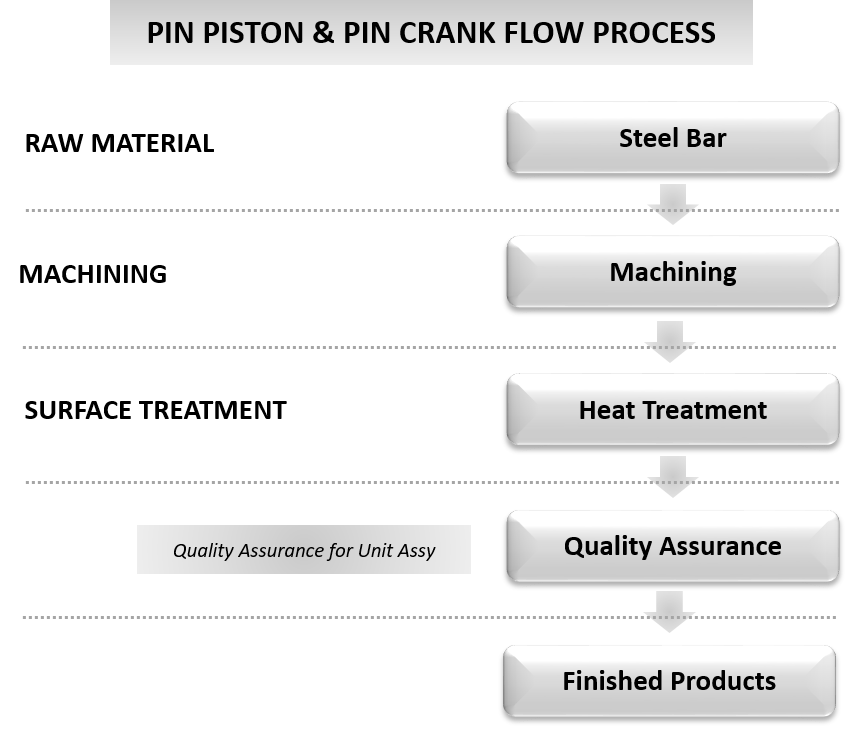

Pin Piston & Pin Crank

Divided into three production lines: Machining Before H/T, Machining After H/T &Assy.

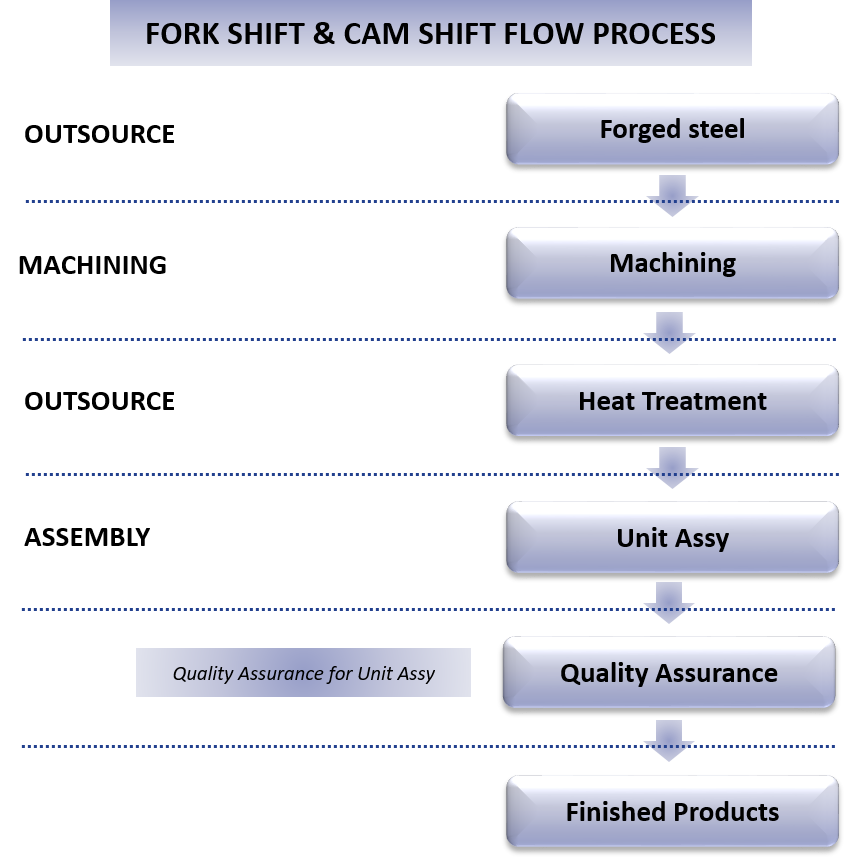

Fork Shift & Cam Shift

Divided into three production lines: Machining Before H/T, Heat Treatment, Machining After H/T. The flow is: